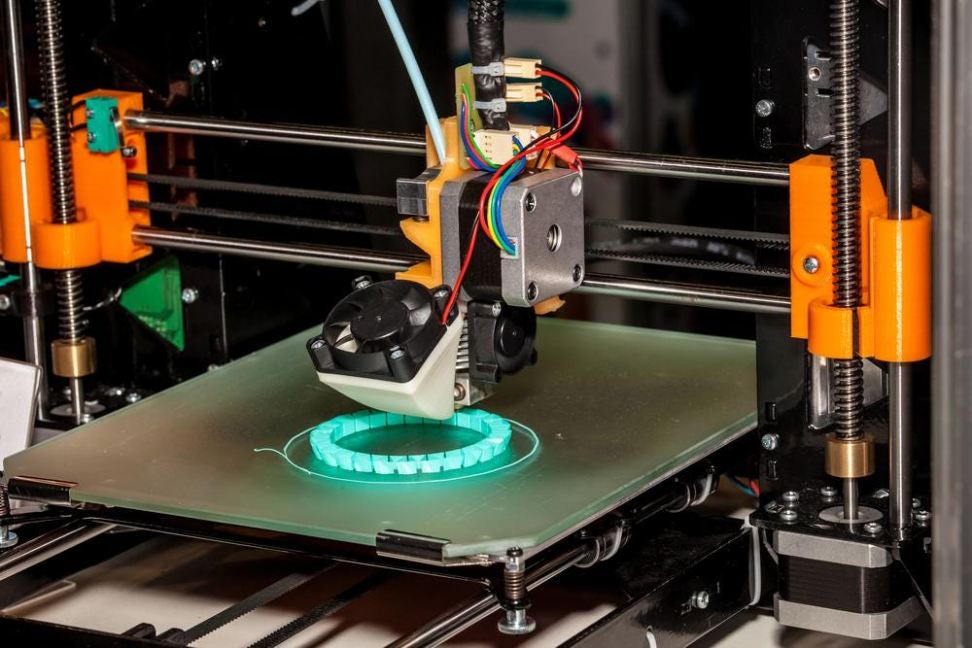

Max66, Arsgroup777, ARS Group Exchange: With the continuous advancements in technology, 3D printing has revolutionized the manufacturing industry by offering numerous benefits. One of the key advantages of incorporating 3D printing in manufacturing processes is the ability to create complex geometries and intricate designs with ease. Traditional manufacturing methods often struggle with producing intricate shapes, but with 3D printing, manufacturers can easily fabricate intricate and detailed parts without any hassle.

Moreover, 3D printing allows for rapid prototyping, enabling manufacturers to quickly iterate designs and test prototypes before moving into full-scale production. This not only speeds up the product development process but also reduces time-to-market significantly. Additionally, the flexibility of 3D printing technology empowers manufacturers to customize products according to specific customer requirements, leading to higher customer satisfaction and increased competitiveness in the market.

� 3D printing enables the creation of complex geometries and intricate designs easily

� Rapid prototyping with 3D printing allows for quick iteration of designs and testing of prototypes

� Customization options in 3D printing lead to higher customer satisfaction

� Reduced time-to-market due to faster product development process

Advancements in Prototyping Techniques with 3D Printing

3D printing has revolutionized prototyping techniques by enabling manufacturers to create intricate models with precision and speed. This technology allows for the production of complex designs that would have been challenging or impossible to achieve using traditional manufacturing methods. With 3D printing, designers can quickly iterate their prototypes, test functionality, and make necessary modifications without the need for expensive tooling or extensive lead times.

Moreover, 3D printing offers the flexibility to produce customized prototypes tailored to specific requirements. By utilizing various materials and printing processes, manufacturers can replicate the look, feel, and functionality of the final product with remarkable accuracy. This level of customization not only accelerates the product development process but also enhances the overall quality and performance of the prototypes, leading to more successful final products in the market.

Reduction in Production Costs through 3D Printing Technology

Ars247, Wazeerexch, Peachexch: One of the key advantages of utilizing 3D printing technology in the manufacturing sector is the significant reduction in production costs. Traditional manufacturing processes often involve expensive tooling and materials, leading to high overhead costs. In contrast, 3D printing allows for cost-effective production by minimizing material waste and eliminating the need for complex tooling.

Moreover, the ability of 3D printers to create intricate designs and prototypes in a single step further contributes to lowering production expenses. This streamlined process results in faster turnaround times, reduced labor costs, and increased efficiency in the manufacturing workflow. As a result, businesses can not only save money on production costs but also increase their overall profitability by leveraging the benefits of 3D printing technology.

How can incorporating 3D printing in manufacturing processes benefit companies?

By using 3D printing technology, companies can reduce production costs, improve efficiency, and speed up the prototyping process.

What advancements have been made in prototyping techniques with the use of 3D printing?

3D printing has allowed for more complex and accurate prototypes to be created quickly and cost-effectively, leading to faster product development cycles.

How does 3D printing technology help in reducing production costs?

3D printing eliminates the need for expensive molds and tooling, reduces material waste, and can streamline the production process, resulting in significant cost savings for companies.

Can 3D printing be used for mass production?

While 3D printing is ideal for prototyping and small batch production, it may not be as cost-effective for large-scale manufacturing due to limitations in speed and material costs.

Additional:

- Provitalize Review 2023

- Kcci – Overview, Net-Worth, Guide

- All You Have To Know About Liteboxer Fitness Bundle Review